There are numerous ways in which companies can attain considerable benefits from utilizing poly bags. Polybags can be useful for functionality and branding purposes. Therefore, businesses can use these bags as marketing vehicles or for services. Notably, poly bags are not the initial items that corporations think of when making efforts to enhance their business outcomes. However, there are numerous reasons to believe and incorporate these bags into a company’s marketing strategies.

Polybags can be used as significant branding materials. Businesses can employ the use of these bags as marketing tools. They can popularize their operations using these bags. Notably, these bags can be used to reach various audiences and target customers. Displaying a business’s logo in high-quality poly bags can assist in attracting potential customers to the business. These small things that many individuals tend to ignore are what usually differentiate a business from its competitors.

Additionally, Poly Bags can act as viable means of saving on shipping. For businesses intending to carry out an enormous project, these bags can serve as the most effective and efficient way of saving on shipping. Companies can use poly bags characterized by lightweight because they are the most efficient ways of saving on a company’s shipping activities.

Further, polybags can be used for facilitating customers’ takeaways. These bags assist customers in keeping the belongings that they are to carry away from a particular company secure. They also ease the process of taking these belongings from the business’s premises. Thus, through utilizing poly bags, a company’s customers will be motivated by the ease and convenience of moving from one place to another while still carrying what they had purchased secured by the bags.

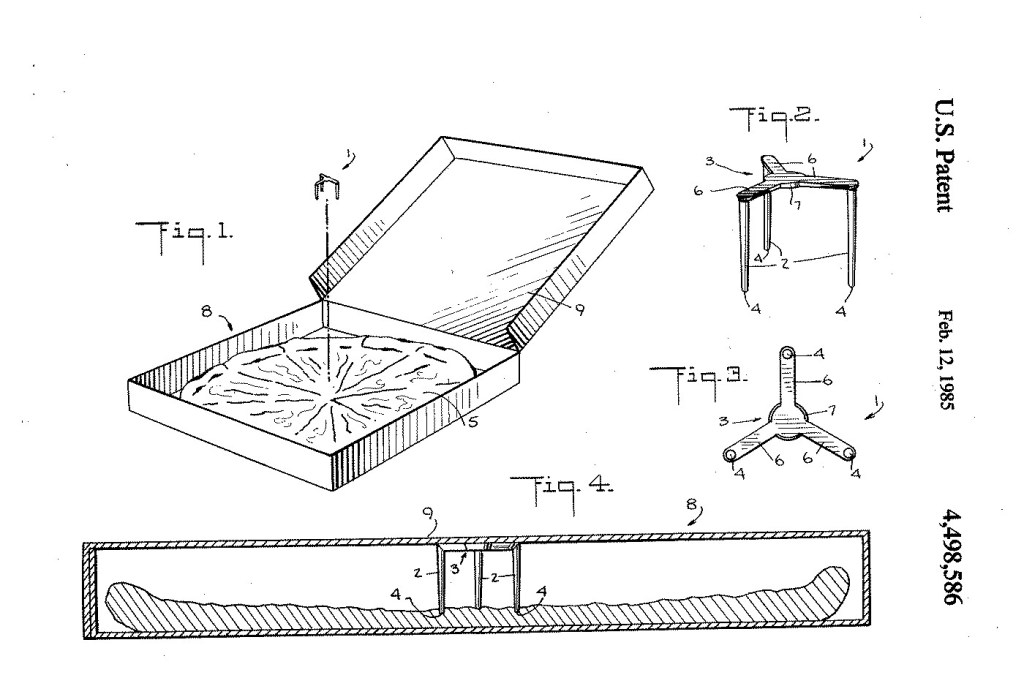

Moreover, poly bags are the best when it comes to distributing food to customers. With poly bags in place, business owners can easily distribute large food items to customers who request this service. Significantly, with the use of poly bags, companies are able to move classy food items to clients who request so safely and securely.

Furthermore, poly bags are also very useful in the medical sector. Polybags are essential items in medical businesses, healthcare establishments, and other organizations in the scientific fields. These bags are very much useful when it comes to not only moving materials and products but also when disposing off them.

Notably, poly bags are also important items at the points of purchase. These bags assist in displaying items as they tend to captivate potential customers. Moreover, they act as useful materials for packaging items in a manner that appears appealing to customers’ eyes. Significantly, they assist in presenting things to the public and also in logistics. They are usually extremely useful at many purchasing points.

In addition, poly bags are useful in the clothing sector. Plastics are frequently used in the apparel industry. Many dry cleaners depend on these bags for any activity that they are carrying out outside the premises. Plastic does outstanding jobs in the clothing field, whether the clothing activity is outbound or inbound.

Additionally, plastics can be used to educate. Polybags can enhance a variety of events in the education field as well as school supplies. With these bags, education-related events can be done in a better manner and successfully organized. Children carrying bags comprising a company’s name on them increase a brand’s popularity besides captivating potential customers.