For many people, even those who work in industries where packing and shipping products is a part of daily life, packing foam is, well, just “packing foam.” If the packing material is soft, and the package seems snug enough to move very little inside the box, then mission accomplished, and off it shipped to its destination. But . . .

Just because a box is filled with packing peanuts as it travels through conventional shipping channels, there’s no guarantee that this conventional method is the safest or the most cost-effective. Not all shipping and packing products are created equal. Everyone has seen (or at least heard of) packages that arrived in dented or wet boxes, and the sensitive and/or valuable contents within were damaged.

Why even mention this? Stuff happens when people ship packages – it’s just a reality of life, right? Maybe this “reality” doesn’t have to be the case. Options do exist that offer both increased durability and lower costs to many conventional packing choices, especially if a business lifeline relies heavily on packing and shipping goods.

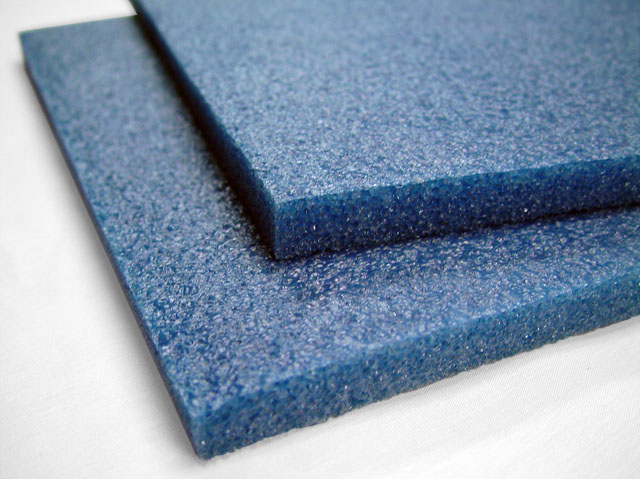

Polyethylene Packing Foam is a type of packing material that most people probably never heard of, let alone would be able to describe. But this type of packing material offers very specific advantages versus other packing alternatives. Polyethylene packing foam is a unique thermoplastic foam that’s soft and firm. It’s also flexible, lightweight, and customizable, all characteristics of which make this foam a sensible, pennywise option.

To begin with, the foam is lightweight. The advantage of lightweight packaging to anybody who works in the shipping industry is obvious. Lighter weight translates into lower costs. In 2021, where the high costs of shipping have priced many smaller companies out of business, saving money on shipping costs is not only a benefit, It is a necessity. Additionally, the weight saved in packaging translates to weight saved in fuel costs to deliver the items. Lower fuel costs, lower emissions, and lower greenhouse gases equate to a very important advantage.

Second, and probably more importantly, polyethylene packing foam’s value is most evident in its durability. This durability comes from the foam’s closed cell construction. In simple terms, this means that the foam acts as a soft layer of protection (a pillow, if you will), surrounding the contents. But the foam is sturdy enough to absorb the bumps and blows that cardboard shipping boxes endure during transit. The foam can be compressed against interior contents without scratching them.

Finally, polyethylene packing foam is very customizable. It comes in convenient rolls. The foam can easily be cut into any shape necessary to fit the very specific needs of varied product shippers. This foam can be unrolled, cut, and fitted to any product dimension or shipping container. It will not lose any of its durability, and, as already discussed, the foam adds minimal extra weight. If a company’s products evolve and change over time, the company’s shipping foam will not have to evolve with them.

The benefits of polyethylene packing foam are clearly evident and quantifiable. Companies whose lifeblood relies on shipping goods should take a hard look at this affordable and convenient option. If you have questions or seek more information about polyethylene packing foam.